Electronic connectors, also known as electrical connectors, are equipment used to join two or more electrical circuits together by conducting electricity between them. Electronic connectors may come in different forms, depending on how you define them. First, electronic connectors can be individual pieces of equipment working to complete the circuit connection. Second, electronic connectors can be a set of connectors working together, like a joined male and female connector set. They can also be any other form of electrical terminal. Also, the circuits themselves can be in the form of cable, or one can be a cable and the other can be an electrical terminal. Read More…

Aries Electronics Inc. manufactures electronic interconnect products and other electronic components. Some products include zero insertion force test sockets, intelligent connectors, adapters, ball grid array sockets, land grid array sockets, high-frequency test sockets, and burn-in sockets.

Interpower is a company that is committed to providing industries with high-quality products. We manufacture electronic connectors. We make it easy for customers to design, build and maintain products for worldwide markets. We use teamwork to provide fast turnaround and great service to our customers.

Quail Electronics is a leading supplier of electrical components such as power cords and appliance electronic connectors. If you don't find what you need in our stock items, we can customize a product to meet needs.

Kord King manufactures world class electronic connectors, electric cords and plugs, electrical receptacles, plug adapters, cord sets and much more. From initial design to development, whether you are looking for a cable assembly or a power supply cord, the experienced team at Kord King delivers rapid order turn-around times and excellent products – consistently adhering to our strict quality...

More Electronic Connector Manufacturers

Applications

Electronic connectors are indispensable components that provide secure and efficient connectivity across a diverse range of industries. These critical devices establish reliable electrical connections, enabling the seamless transfer of power, data, and signals between various electronic components and systems. Their fundamental role in modern electronics ensures the high performance, safety, and adaptability of countless applications.

Within printed circuit boards (PCBs), electronic connectors facilitate the integration and electrical continuity between discrete board elements. By allowing signals, current, and data to travel between modules, connectors are essential for the operation of virtually all electronic devices—including smartphones, tablets, laptops, and desktop computers. Without reliable PCB connectors, the compact and modular design of today’s electronic products would not be possible.

Looking for connectors for audio and video equipment? DIN connectors are widely used in loudspeakers, amplifiers, and a host of AV systems. Their standardized, circular design reduces the risk of misalignment or faulty connections, thereby enhancing audio performance and overall device reliability. You’ll also find DIN connectors in electric guitars, synthesizers, and television audio-visual setups, where robust, interference-free transmission is critical for professional-grade sound and image quality.

For applications where durability is paramount—such as in military and aerospace electronics—specialized connectors that meet stringent military specifications (MIL-SPEC connectors) are used. These ruggedized electronic connectors are engineered to withstand extreme temperatures, vibration, moisture, and mechanical shock. They play a vital role in military communication systems, avionics, radar, navigation, and power distribution, safeguarding mission-critical operations in the harshest environments.

Wondering how connectors impact everyday devices? In the consumer electronics industry, connectors are found in mobile phones, tablets, wearable devices, and telecommunications hardware. They enable high-speed charging, rapid data transfer, and seamless peripheral interfacing, all of which contribute to intuitive and uninterrupted user experiences. In the medical sector, connectors are subject to rigorous regulatory and safety standards. Their precision and reliability ensure accurate signal transmission and continuous power supply in diagnostic equipment, patient monitoring systems, and life-support devices—where failure is simply not an option.

How do connectors boost vehicle safety and performance? The automotive industry leverages a wide variety of electronic connectors for engine control units (ECUs), infotainment systems, advanced driver assistance systems (ADAS), sensors, and lighting assemblies. Automotive-grade connectors facilitate real-time communication between components, contributing to enhanced safety, reliability, and the integration of smart vehicle technologies such as electric powertrains and autonomous driving features.

The industrial and commercial sectors rely on robust connectors for demanding applications in data centers, industrial automation, robotics, and manufacturing. In data centers, high-performance connectors support fast, reliable connections between servers, network switches, and storage arrays, ensuring uninterrupted data flow and minimal downtime. Industrial environments employ connectors in programmable logic controllers (PLCs), control panels, factory automation systems, and sensor networks, where durability and resistance to harsh conditions are essential for maximizing uptime and productivity.

Overall, electronic connectors are versatile and mission-critical components underpinning modern technology. They guarantee smooth power delivery, rapid signal transmission, and reliable communication between devices, systems, and infrastructure. Whether you’re designing consumer electronics, configuring industrial automation, or specifying military-grade systems, the right connector choice is essential to ensure performance, longevity, and future scalability.

How Electronic Connectors Work

Electronic connectors function as the physical and electrical interface between two or more electronic components, devices, or systems. Their design ensures a secure mating between male and female terminals, creating a continuous conductive path for electrical current, signals, or data. Whether you’re assembling a PC, wiring industrial machinery, or setting up a telecom network, understanding how connectors work is crucial for system reliability and safety.

Inside every connector are precision-engineered pins, blades, or sockets—typically made from highly conductive metals such as copper, gold, silver, or their alloys—to achieve low electrical resistance and high signal integrity. When connected, these contacts align to form a secure path for current or data transmission. Many connectors feature guiding keys, polarization features, and mechanical locks. These design elements ensure proper alignment, prevent incorrect mating, and secure the connection against accidental disconnection due to vibration or mechanical movement.

Do you need a connector for alternating current (AC) or direct current (DC) applications? The nature of the electrical signal—whether AC or DC—directly influences connector selection. AC connectors are optimized for applications involving periodic current reversal and high-frequency signals. They are designed with considerations for impedance, capacitance, and inductance to minimize signal loss or distortion, making them ideal for power distribution, audio/video equipment, and high-speed data systems.

Conversely, DC connectors are engineered for applications where current flows in a single, constant direction. Their primary focus is minimizing resistance and ensuring stable power delivery—critical for power adapters, battery-powered electronics, and digital data transfer systems. Choosing between AC and DC connectors involves evaluating voltage, current ratings, frequency response, and environmental exposure.

What makes a connector reliable under harsh conditions? The answer lies in advanced contact materials and robust housing designs. Contacts are often plated with gold or nickel to resist corrosion and maintain conductivity over thousands of mating cycles. Housings made from high-grade plastics, thermoset resins, or metal alloys provide mechanical protection and environmental sealing, safeguarding the internal contacts from dust, moisture, chemicals, and mechanical abuse.

In summary, electronic connectors are vital for efficient signal and power transmission across all electronic domains. Choosing the right connector type—considering current type (AC vs. DC), mechanical requirements, and environmental conditions—ensures optimal system performance, safety, and longevity. For complex or mission-critical applications, consult with connector manufacturers or electronic design engineers to specify the best solution for your needs.

Electronic Connector Design Considerations

Designing electronic connectors involves a careful balance of mechanical, electrical, and environmental requirements. Manufacturers consider multiple factors to ensure connectors meet the specific needs of their intended applications. Key design considerations include:

- Connection Requirements: What components or systems are being linked? Is the connection permanent or temporary?

- Ambient Temperature Range: Will the connector be used in environments with extreme heat, cold, or rapid temperature fluctuations?

- Mechanical Stress: How much vibration, shock, or repetitive movement will the connector endure?

- Compatibility: Does the new connector need to interface with existing legacy connectors, cables, or PCBs?

- Mating Frequency: How often will users plug and unplug the connector? High-cycle connectors require more durable materials and locking mechanisms.

Based on these criteria, manufacturers define technical specifications such as pitch (the distance between the centers of adjacent contacts), mating cycles (the expected lifespan of the connector under repeated use), voltage and current ratings, and overall form factor. Special attention is given to pin layout, housing materials, and sealing features to ensure robust performance in the intended environment.

Are you seeking custom connector features? Manufacturers offer a wide range of customizable options, including:

- Additional contacts for complex signal or power requirements

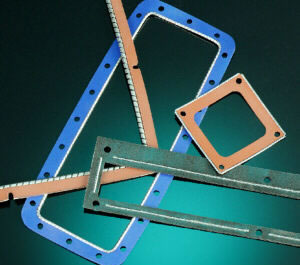

- Seals (gaskets or O-rings) to protect against dust, oil, moisture, and corrosive agents

- Corrosion-resistant anodized shells for marine, outdoor, or industrial use

- Strain relief and cable clamps to prevent damage from mechanical forces

- Unique keying and locking features to prevent improper mating

The ability to tailor connectors to unique project demands is a key advantage. For highly specialized or regulated industries, such as aerospace, automotive, or medical electronics, collaboration with experienced connector manufacturers is essential to meet safety, reliability, and compliance standards. Need help with a custom electronic connector design? Contact leading electronic connector manufacturers to discuss your application and obtain expert guidance.

Key Features of Electronic Connectors

All electronic connectors share several core features that define their function, performance, and usability:

- Contacts/Terminals: The conductive elements (pins, blades, sockets) that establish the electrical connection. High-quality contacts are essential for low-resistance, high-integrity connections. Male contacts are often called “pinouts,” while female contacts are known as “receptacles” or “sockets.”

- Housing: The insulating enclosure that protects the contacts from environmental hazards and mechanical impact. Most housings are made from high-durability plastic, thermoplastic elastomer, or insulating composites.

- Locking Mechanisms: Features such as latches, clips, or threaded couplings that prevent accidental disconnection and secure the mating halves together.

- Keying/Polarization: Design elements that ensure connectors can only be mated in the correct orientation, preventing improper connection and damage.

Premium connectors may also include features like environmental sealing, EMI/RFI shielding, and integrated strain reliefs to enhance reliability in demanding conditions. The choice of materials—such as phosphor bronze, beryllium copper, or brass for contacts—further improves conductivity and longevity.

Types of Electronic Connectors

Electronic connectors are classified by connection method, gender, physical form factor, and application. The primary types include:

- Temporary Connectors: Used for portable or modular equipment where frequent connection and disconnection are expected. Examples include USB connectors, headphone jacks, and test probes.

- Assembly-Required Connectors: Designed for equipment that may require future servicing or upgrades. These connectors are removable but offer greater durability than temporary types.

- Permanent Connectors: Intended for long-term, fixed installations where disconnection is rare or undesirable. Often used in internal device wiring or embedded systems.

Gender classification:

- Male Connectors: Feature metal prongs or pins that insert into corresponding sockets (female connectors). Common in plugs, pin headers, and blade connectors.

- Female Connectors: Receive the male connector’s pins or blades. Examples include wall sockets, receptacles, and slot-type connectors.

Curious about which type fits your application? Here are some common connector categories and their use cases:

- Pin Connectors: Use metal pins to create circuit connections, typically as part of a plug-and-socket assembly. Widely used in industrial controls, instrumentation, and power distribution boards.

- Cable Connectors: Join cable cords to electronic devices, enabling flexible routing of power and signals. These include plug, screw, or clamp mechanisms for secure attachment.

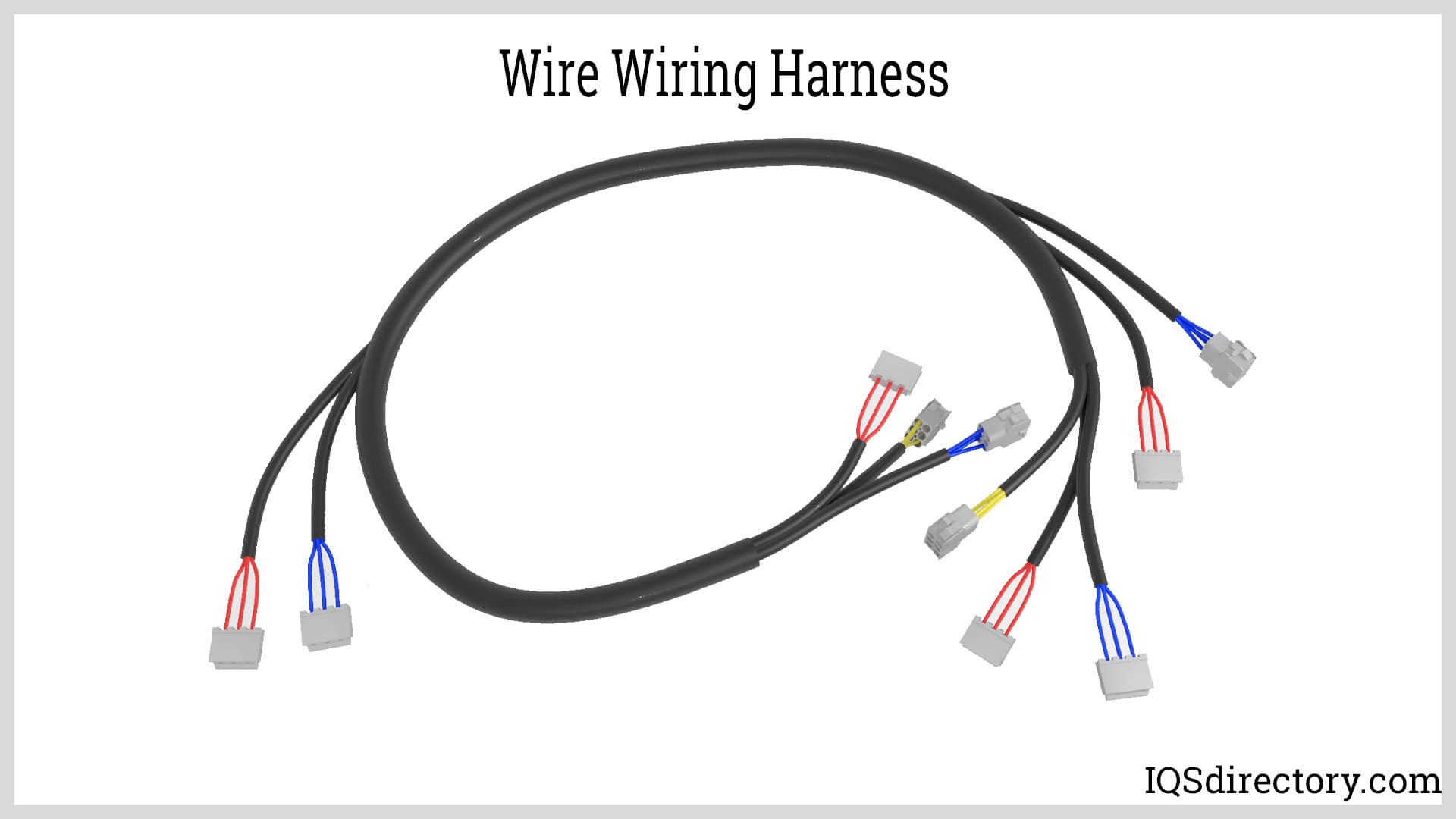

- Wire Connectors: Encompass a broad range of connectors for joining or terminating wire leads. Examples include twist-on wire nuts, crimp terminals, and spring connectors.

- Fiber Optic Connectors: Utilize fine glass fibers to transmit light-based signals with minimal loss. Essential for high-speed telecommunications, data networking, and medical imaging systems.

- Amp Connectors (Amphenol): Heavy-duty connectors capable of transferring significant amperage, used for AC or DC power in battery banks, solar PV systems, and industrial equipment.

Specialized and less-common connector types include:

- DIN Connectors: Standardized by the Deutsches Institut für Normung (DIN), these circular connectors are popular in audio, instrumentation, and industrial automation.

- Coaxial Connectors: Designed for high-frequency RF (radio frequency) signals, including BNC, SMA, and F-type connectors. Used in cable television, radio transmitters, and test equipment.

- PCB Connectors: Compact connectors designed for direct mounting on printed circuit boards, supporting high-density layouts in computers, medical equipment, and consumer devices.

- RF Connectors: Specialized coaxial connectors optimized for minimal loss and interference at radio frequencies. Examples include N-Type, TNC, and MCX connectors.

- Waterproof Connectors: Feature seals and gaskets to prevent water ingress, suitable for outdoor lighting, marine, and automotive electronics.

- Power Connectors: Engineered to handle high currents and voltages, commonly used in industrial power supplies, electric vehicles, and backup power systems.

Need help choosing the right connector? Explore our comprehensive electronic connector manufacturers directory for expert advice and product sourcing.

Advantages of Using Electronic Connectors

Why select electronic connectors over alternatives such as soldered joints or wireless technology? The benefits are wide-ranging and critical for both simple and complex systems:

- Modularity: Connectors enable modular system design, making it easy to assemble, upgrade, or repair electronic equipment without damaging PCBs or wiring harnesses.

- Serviceability: Faulty components can be replaced quickly, reducing downtime and minimizing maintenance costs. This is especially valuable in data centers, industrial automation, and mission-critical applications.

- Reliability: Mechanical locking features, polarization, and robust materials ensure stable, low-resistance connections that maintain signal integrity even in harsh conditions.

- Compatibility and Standardization: Adherence to industry standards ensures interoperability between devices from different manufacturers, broadening your options for replacement and expansion.

- Security: Physical connectors provide enhanced security and data protection, minimizing the risks associated with wireless interference, hacking, or unauthorized access.

- Performance: For high-speed data transfer and low-latency applications, physical connectors outperform wireless alternatives by delivering higher bandwidth with less susceptibility to environmental interference.

- Safety: Compliance with UL, IEC, or MIL-SPEC standards guarantees electrical safety for users and equipment.

When compared to soldered connections, connectors allow for quick assembly, reconfiguration, and maintenance without specialized tools. While wireless communication (e.g., Wi-Fi, Bluetooth, NFC) offers convenience, it often falls short in terms of data transfer rate, range, and signal reliability for critical or high-performance applications. In summary, electronic connectors deliver the flexibility, durability, and performance required for today’s advanced electronic systems.

Electronic Connector Accessories

Maximize the performance and longevity of your electronic connectors by selecting the right accessories. Accessories provide additional protection, adaptability, and installation convenience. Common types include:

- Bushings: Offer mechanical support and reduce strain on the connector interface, especially for panel-mount or bulkhead connectors.

- Contacts and Terminals: The internal conductive elements that can be replaced or upgraded for specific current or signal requirements.

- Dust Caps: Safeguard connector mating surfaces from dust, debris, and moisture when not in use, extending service life.

- Adaptors: Facilitate interconnection between different connector types, sizes, or standards, ensuring compatibility in mixed-system environments.

- Wire Terminal Kits: Provide assorted terminals, splices, and crimp connectors for custom cable assembly and field repairs.

- Repair Kits: Contain essential tools and parts for on-site connector repair, minimizing downtime during equipment maintenance.

When sourcing accessories, consider factors such as environmental exposure, mechanical stress, and compatibility with your connectors and cables. Leading manufacturers, authorized distributors, and online electronics suppliers offer a broad selection of genuine accessories to suit every application. Proper accessory selection enhances reliability, protects your investment, and optimizes electronic system performance.

Proper Care and Maintenance of Electronic Connectors

Are you getting the most out of your connectors? Proper care and routine maintenance are essential for maximizing the lifespan and performance of electronic connectors. Here’s how to keep your connections secure and trouble-free:

- Handle with Care: Avoid excessive force when connecting or disconnecting, especially with temporary connectors that see frequent use. Repeated rough handling can cause wear, vibration-induced damage, or bent contacts.

- Inspect for Damage: Regularly examine connectors for physical signs of wear, corrosion, or bent pins. Early detection of issues can prevent costly downtime and system failures.

- Prevent Contamination: Keep connector surfaces clean and free from dust, oil, or chemicals. Use dust caps or covers when connectors are not in use, and only clean with approved, non-abrasive solutions.

- Mitigate Environmental Risks: Protect connectors from exposure to moisture, extreme temperatures, and corrosive substances. For outdoor, marine, or industrial applications, specify connectors with appropriate ingress protection (IP) ratings and corrosion-resistant materials.

- Monitor Connection Cycles: Track how often connectors are mated and unmated, particularly for high-cycle applications. Replace connectors as recommended by the manufacturer to ensure ongoing reliability.

Adhering to these best practices ensures consistent performance, reduces the risk of unexpected failures, and extends the service life of your electronic connectors.

Buyer’s Guide: Things to Consider When Choosing Electronic Connectors

Ready to source electronic connectors for your next project? Making the right selection involves more than just choosing a connector that “fits.” Here are key factors to guide your buying decision and maximize ROI:

- Application Requirements: Clearly define the function, environment, and performance needs of your application. Is the connector for signal, power, or data? Will it be exposed to vibration, moisture, or corrosive chemicals?

- Technical Specifications: Know the required voltage, current rating, frequency, and bandwidth. Ensure the connector can handle these electrical loads safely and efficiently.

- Standards and Compliance: Determine if your project must meet specific certifications (UL, CE, RoHS, IEC, MIL-SPEC) for safety, environmental, or industry requirements.

- Quantity and Budget: Establish the number of connectors needed and your project budget. Bulk orders may qualify for volume discounts from manufacturers or distributors.

- Lead Time and Delivery: Factor in expected delivery times, especially for custom or specialty connectors. Reliable suppliers provide realistic timelines and transparent communication.

- Supplier Reputation: Choose reputable, highly rated manufacturers or authorized distributors. Evaluate product reviews, support resources, and post-sales service to ensure a positive purchasing experience.

How do you identify top suppliers? Start by reviewing our curated list of leading electronic connector manufacturers in North America. Each profile includes links, product information, and direct contact details to streamline your research and decision-making process.

Before contacting suppliers, outline your requirements in detail—application type, electrical specs, compatibility needs, and target delivery dates. Compare product offerings, pricing, customer support, and industry certifications. Shortlist three or four top contenders, request samples or datasheets, and engage in discussions to clarify any technical questions. A supplier who is invested in your success will offer expert advice and responsive support throughout your project lifecycle.

Need help getting started? Contact trusted electronic connector manufacturers today to discuss your application, request quotes, and arrange product demonstrations. Making an informed choice ensures your electronic systems are reliable, future-proof, and optimized for performance in any environment.

Frequently Asked Questions (FAQ) About Electronic Connectors

- What types of electronic connectors are best for outdoor use? Look for waterproof or weatherproof connectors with high IP ratings, corrosion-resistant materials, and robust sealing.

- How do I select a connector for high-speed data transmission? Focus on connectors designed for low signal loss, high shielding effectiveness (EMI/RFI), and compatibility with your data protocol (e.g., USB 3.1, HDMI, Ethernet).

- What are the most important safety certifications for electronic connectors? UL, IEC, CE, RoHS, and MIL-SPEC certifications indicate adherence to key safety, environmental, and performance standards.

- Can I customize connectors for unique requirements? Yes, most manufacturers offer custom connector design services to meet specific mechanical, electrical, and regulatory needs.

- Where can I find reliable electronic connector suppliers? Visit our manufacturer directory for vetted, reputable sources across North America.

Use Cases and Industry Applications

- Consumer Electronics: Charging ports, audio/video jacks, and data interfaces in smartphones, tablets, and laptops.

- Automotive: Engine control, infotainment, sensors, lighting, and EV battery connectors.

- Industrial Automation: Machine control, robotics, PLCs, and sensor networks.

- Medical Devices: Patient monitors, diagnostic equipment, imaging systems, and implantable devices.

- Telecommunications: Network infrastructure, fiber optic links, routers, and switches.

- Data Centers: Server interconnects, power distribution units, and high-speed networking.

- Aerospace and Defense: Avionics, radar, communications, and satellite systems.

- Renewable Energy: Solar panel arrays, wind turbines, and battery storage systems.

- Marine and Outdoor: Navigation, lighting, and control systems exposed to harsh environments.

Ready to Find the Perfect Electronic Connector?

Start your search by browsing our extensive directory of electronic connector manufacturers and suppliers. Use filters to compare products by type, application, certification, and region. For personalized recommendations, contact suppliers directly to discuss your project requirements, request quotes, or arrange technical consultations. Make your next electronic system more reliable, modular, and future-ready with the right connector solution.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services